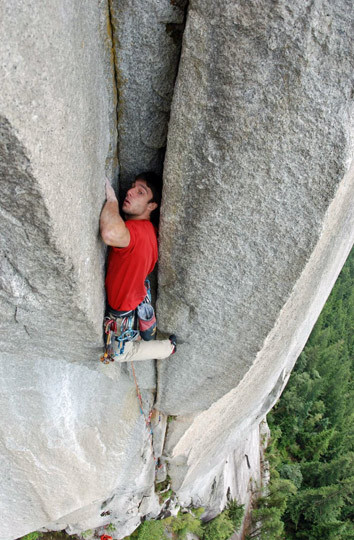

Matt Maddaloni on University Wall (IV 5.12 900′), Squamish. Maddaloni used one of Squamish’s detached flakes as testing grounds for the Anticam, a new type of climbing hardware of his own invention. [Photo] Paul Cordy

Two-thousand pounds of nearly detached rock–tapering from a meaty 18 inches down to a guillotine-like edge–dangle above Matt Maddaloni. As much as he wants to send the route, his instincts implore him to flee. Perhaps there’s a good reason the Guillotine Flake has never been climbed.

Maddaloni is 600 feet off the deck on the most classic pitch of the most classic climb on the most impressive wall at one of the best places to climb in the world. The Split Pillar section of The Grand Wall (III 5.11 A0, 1,000′) on Squamish’s The Chief. This 5.10b splitter streaks up flawless granite, progressing from wide fingers to rattly fists. Looming above Maddaloni, at the top of the pitch, is the beautiful–and horrifying–Guillotine Flake. He weighs his options. There are only a few. He could try to protect it with natural pro, but the couple of cams he tried placing failed under less than body weight. Big bros or larger cams would do the same or worse–pry the 2,000-pound block off the wall. He could make the traverse without placing pro, risking a 70-foot whipper into the wall. He could protect the traverse with bolts… no way. Or he could take a more outlandish approach: create an entirely new piece of protection that would allow him to safely lead the pitch.

For more than 15 years, Maddaloni has called Squamish home. He’s put up numerous long free and aid routes on Zodiac and the Grand Wall, including The Black Dyke (V 5.13b, 12 pitches) and Cro-Magnon Man (V 5.9 A4). From 2000 to 2007, he climbed professionally, establishing routes from Pakistan to Thailand and from Baffin Island to the Waddington Range. His appetite for climbing was insatiable.

After years of whippers, jet lag and cramping feet Maddaloni felt like his climbing potential had peaked. He felt burned out. So he moved on to other things. He entertained an infatuation with kiteboarding and found love on the river with whitewater kayaking. But each time, those passions faded.

In 2001 Maddaloni came across the unclimbed Guillotine Flake while taking a lap on The Grand Wall and was immediately intrigued. But how would he protect the loose and dangerous flake with natural gear? The piece would need to be strong, withstanding a minimum force of 10 kN; highly expandable to fit a wide range of features; light and compact enough to hang on a harness or place with one hand. But that style of pro didn’t exist. He would have to make it himself.

The Guillotine Flake, Grand Wall, Squamish. Maddaloni made the first ascent of this single-pitch, expanding flake using a new piece of pro called the Anticam. [Photo] Matt Maddaloni

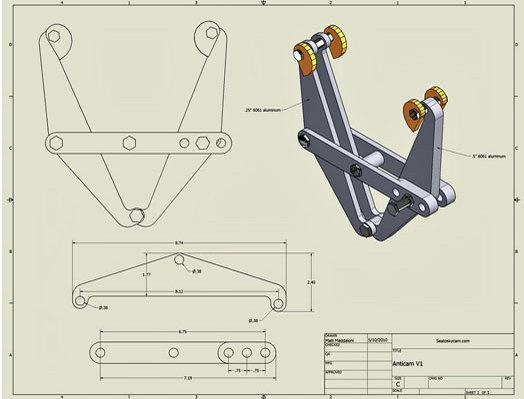

Maddaloni’s imagined solution was a C-shaped clamp. Unlike a friend or tricam that expands during a fall, the clamp would pinch the rock. He began designing the parts on his computer using a mechanical engineering program. He drew each part, connected them together and moved them around with his mouse to get an idea of how the pro would work. He virtually tested each prototype using a digital process that showed Maddaloni where the strongest and weakest points on the device would be.

“The first prototype was pretty crude but in theory it worked,” Maddaloni said.

The “Anticam” prototype resembled an open mouth with twin jaws of aluminum and cam lobes for fangs. At the back of the mouth a stabilizer bar held the jaws in place. Pulling on a thin piece of nylon cord caused the jaws to bite. To place the Anticam, Maddaloni had to unscrew a bolt, widen the device to the appropriate width and bolt it back together. It took two hands to set; one hand holding it in place while the other pulled back the cord that engaged the lobes.

A technical drawing of Version 1 of the Anticam with a removable bolt that allowed Maddaloni to expand and place the gear with one hand and a cord to engage the lobes with the other. Though Version 1 did hold short falls it was bulky, had a limited expansion range and required two hands to place. [Photo] Matt Maddaloni

Once Maddaloni assembled the Anticam, he tested it on a similarly unprotectable flake on the Neat and Cool Wall in Squamish. He tied into the sharp end and placed some natural gear on a large detached flake to prevent him from decking in case the Anticam failed. Just above his last piece, he carefully placed his invention, giving it a few stout tugs to build his confidence. He positioned himself in a wide stance and gently weighted the rope. It held. He climbed above it and jumped off. Instantly it popped free. Failure. He quickly moved back into position on the climb, this time placing the Anticam on a thinner, more uniform section of the flake. He weighted the rope. The gear held. With more confidence, Maddaloni climbed until the Anticam was at his toes and bounced backwards off the wall. Again, it held. A fifty-fifty ratio of success so far.

Though the first Anticam successfully held short hops down the wall, Maddaloni knew it could be improved. The prototype was bulky, weighing 2 lbs and measuring 10 by 12 by 3 inches. It wasn’t nearly as versatile as Maddaloni had hoped for, and it failed to fulfill his original requirements: able to be placed with a single hand and highly expandable to fit both fat and thin flakes.

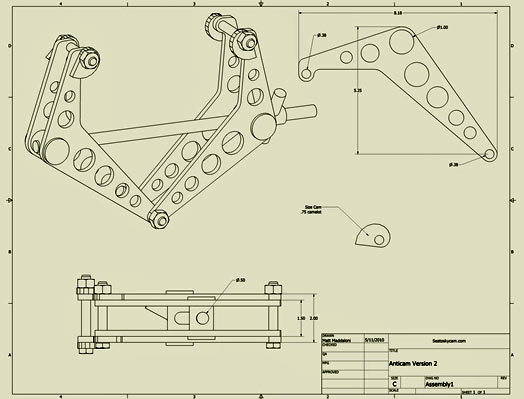

Maddaloni’s five subsequent versions of the Anticam featured small improvements over the prototype. He drilled coin-sized holes in each of the three aluminum arms to decrease the weight while maintaining strength. He also altered the springs on the lobes so that they rolled in the opposite direction of a normal cam, which enabled him to forgo a trigger. The most important alteration was that of the perpendicular bar, originally used for stability. In later versions, Maddaloni used the bar to increase expansion of the Anticam’s arms by using a threaded rod. The alterations gave the Anticam a huge expansion range–from zero to nine inches–and enabled it to be placed with one hand.

After tinkering with every feature–from the size of the cam lobes to the number of coils in the springs that manipulated them–Maddaloni felt ready to test the invention on the Guillotine Flake itself. He brought the three most promising versions of the Anticam to The Chief to “mock lead” the traverse, placing the gear on lead while also supported by a toprope. He quickly realized that only one of the three Anticams would work. The version that worked best was the one without a trigger, which had allowed Maddaloni to adjust each lobe independently. Without this adjustment, the rock would need to be completely level and flat so all the Anticam’s lobes would have good contact with the slab. Maddaloni headed back down the wall and back to the drawing board. A week later, with three copies of the most successful version of the Anticam jingling on his harness, he returned to the Guillotine.

Version 2 of the Anticam with a few improvements over the prototype. The most notable change is the threaded rod that gave the Anticam a broader expansion range and allowed it to be placed with one hand. [Photo] Matt Maddaloni

Beginning at the top of the Split Pillar pitch on The Grand Wall, Maddaloni climbed 20 feet up the famous Sword Pitch where the flake first splits from the wall. Here the flake is only an inch thick and frighteningly hollow. The flake then curves out right for eight feet before drooping down another 15 feet. Maddaloni placed a few nuts and traversed out onto the brittle rock to the low, five-inch-thick point of the flake. Belayer Adam Hart watched as the whole feature flexed with the careful balance of tension between the pull of Maddaloni’s arms and the push of his feet.

Just past the apex Maddaloni began placing Anticams every 10 feet. The flake had thickened enough that a fall onto the gear wouldn’t break the edge off the slab but would still fit the Anticam’s nine-inch range. To let go with one hand and place gear required getting his feet high on the blank wall and locking off with a 90-degree bent arm. The prototypes were awkward and required care to place properly. After placing three Anticams, his arms were “screaming” for a rest, but Maddaloni still had to run it out to the point where he could finally place normal cams. Halfway through the unprotected section, he didn’t think he would make it with the little energy he had left.

“I looked back and imagined my fall–popping off the three homemade, alien-looking contraptions and slamming into the corner at full speed,” Maddaloni said. “At that point it might as well have been the ground I’d slam into.”

He tried to place a friend before reaching the “safe zone,” but didn’t have the strength and knew it wouldn’t hold anyway. He had to trust his invention. Maddaloni continued the traverse, placing his first solid cam a full 20 feet from his last Anticam placement and finally shaking out on the only foot hold on the entire pitch.

“I couldn’t stop smiling all the way to the bar… After that route I realized climbing still held a lot of unknowns for me. Exciting challenges awaited, and I didn’t need to get stronger or climb scarier things to achieve that,” Maddaloni said.

Later that summer he discovered the biggest roof in the Squamish area–a “whopping” 60-foot horizontal line that required every technique, including some he hadn’t perfected yet. Maddaloni challenged himself with the technical and delicate knee bars, upside-down offwidths and dynos into hand jams.

“There were endless possibilities. I just had to look with new eyes.”

Four versions of the Anticam on display on the door frame of Maddaloni’s workshop. [Photo] Matt Maddaloni